What influences your bespoke staircase cost

A bespoke staircase is more than a means of moving between floors—it is often the architectural heart of a home. A well-designed staircase offers both beauty and functionality while reflecting your personal style. But with custom design comes a tailored price tag. Understanding the cost of a new staircase means appreciating the fine balance of design, material selection, features, and expert craftsmanship.

This guide will walk you through the key factors that influence the price of a new staircase. At Apex Staircases, we combine luxury craftsmanship with transparent pricing. Our goal? To ensure that every UK homeowner understands where their investment goes and what value they receive.

Design complexity and structural considerations

The shape and structural requirements of your staircase are among the biggest drivers of cost. The more complex the form, the more specialised the engineering and labour.

Type of Staircase

- Straight: The simplest and most affordable design.

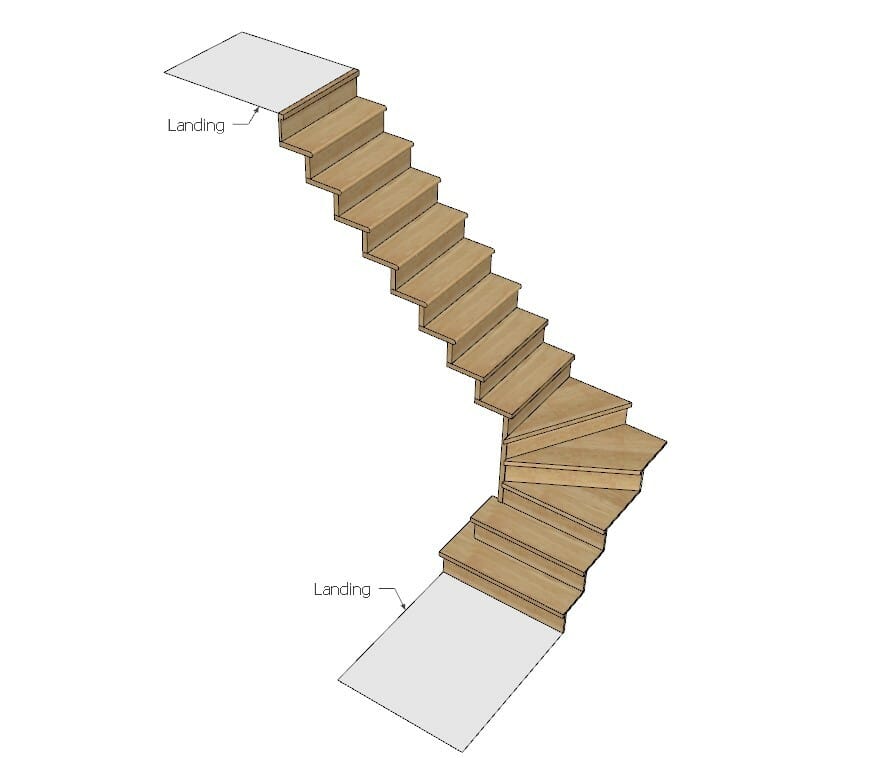

- L-Shaped / Quarter Turn & U-Shaped / Half Turn: Increased complexity due to landings and transitions.

- Spiral / Helical: High-end and intricate; require specialist fabrication, custom parts, and advanced structural calculations.

- Open Riser / Floating: Visually striking with concealed support systems; higher investment due to precision engineering.

Structural Requirements

- Integration with the building: Load-bearing roles, adjustments to existing architecture, or extensive reinforcement add cost.

- Custom dimensions: Non-standard height, width, or turning radius calls for tailored fabrication.

- Cantilevered/Floating designs: Require advanced engineering and concealed fixing methods.

Material selection and finishing

The materials you choose for your new staircase play a crucial role in both its aesthetic appeal and its final cost. Different materials offer varying levels of luxury, durability, and fabrication complexity.

Treads & Risers:

- Timber: The cost of timber varies widely depending on the species. For instance, pine is generally more economical, while oak staircases or exotic hardwoods like walnut staircases represent a greater investment due to their inherent beauty, strength, and scarcity. Solid timber treads are also more expensive than veneered options.

Balustrades & Handrails:

- Timber: A traditional choice, with costs varying by wood type, similar to treads.

- Glass Panels: Highly popular for their minimalist appeal and light-enhancing properties, but thicker, toughened glass panels are a significant cost factor.

- Metal (Spindles, Rods, Wires): Options range from simple mild steel spindles to intricate wrought iron designs.

- Combinations: Blending different materials, such as a metal frame timber tread staircase, can create truly unique and stunning looks but often adds to the complexity and thus the cost of a new staircase.

Finishes:

- Specialist Finishes: If you opt for high quality varnishes, bespoke stains, intricate hand-painted details, or specialised powder coating for metals, these will incur additional costs due to the extra labour and materials involved.

What Influences Your Bespoke Staircase Cost

A bespoke staircase is more than just a way to move between floors; it’s a significant investment, often becoming the architectural heart and a captivating focal point of your home. While the allure of customisation offers unparalleled beauty, functionality, and a true reflection of your personal style, it naturally comes with a tailored price tag. Understanding the new staircase cost means appreciating the intricate balance of design, materials, and expert craftsmanship involved.

This article will break down the key factors that contribute to the final cost of a new staircase, helping you understand precisely where your money goes. At Apex Staircases, we believe in combining luxury craftsmanship with transparent pricing, ensuring that the new staircase cost UK homeowners encounter reflects the exceptional quality, meticulous compliance, and enduring value you receive.

The foundation: design complexity and structural considerations

The complexity of your staircase’s design and its structural requirements are often the primary drivers of its overall cost. The more intricate the form and the more specialised the engineering, the higher the investment.

Type of Staircase:

- Straight: Generally the simplest design, making it the most cost-effective option.

- L-Shaped / Quarter Turn & U-Shaped / Half Turn: These designs involve more complex landings and turns, which increases the fabrication and installation costs due to additional components and precise fitting.

- Spiral / Helical: These are highly complex. Their intricate curves require advanced calculations, specialised machinery, and meticulous fabrication, leading to significantly higher costs.

- Open Riser / Floating: While visually striking, these can be more expensive due to specialised structural requirements, such as hidden supports and precise wall fixings to create the illusion of weightlessness.

Structural Requirements:

- Building Integration: Does your new staircase need significant structural support from the building itself? Or is it a load-bearing element that will carry the weight of a floor above? More complex integration with existing architecture can significantly increase labour and material costs.

- Unique Features: Custom curves, unusual angles, or non-standard dimensions will always add to the cost.

- Cantilevered or ‘Floating’ Designs: These are at the higher end of the spectrum. They involve highly complex engineering and specialised hidden fixing mechanisms that create their distinctive, unsupported look, pushing costs up considerably.

The canvas: material selection and finishes

The materials you choose for your new staircase play a crucial role in both its aesthetic appeal and its final cost. Different materials offer varying levels of luxury, durability, and fabrication complexity.

Treads & Risers:

- Timber: The cost of timber varies widely depending on the species. For instance, pine is generally more economical, while oak staircases or exotic hardwoods like walnut staircases represent a greater investment due to their inherent beauty, strength, and scarcity. Solid timber treads are also more expensive than veneered options.

- Steel/Metal: The cost of metal treads varies with the type of steel (e.g., mild steel vs. polished stainless steel) and the complexity of its fabrication and finishing.

Balustrades & Handrails:

- Timber: A traditional choice, with costs varying by wood type, similar to treads.

- Glass Panels: Highly popular for their minimalist appeal and light-enhancing properties, but thicker, toughened glass panels are a significant cost factor.

- Metal (Spindles, Rods, Wires): Options range from simple mild steel spindles to intricate wrought iron designs or sleek, polished stainless steel rods and wires, each with its own price point.

- Combinations: Blending different materials, such as a metal frame timber tread staircase, can create truly unique and stunning looks but often adds to the complexity and thus the cost of a new staircase.

Finishes:

- Standard Finishes: High-quality varnishes, paints, or basic stains are typically included in the overall cost.

- Specialist Finishes: If you opt for high-gloss, bespoke stains, intricate hand-painted details, or specialised powder coating for metals, these will incur additional costs due to the extra labour and materials involved.

Beyond the basics: features and functionality

While the core structure and materials form the bulk of the new staircase cost, optional additions can significantly enhance both its functionality and its final price. These bespoke features truly elevate your staircase from a simple structure to a personalised masterpiece.

Consider these additions:

- Integrated Lighting: LED strips seamlessly embedded under treads or sleek, wall-mounted lights can create dramatic effects and improve safety. However, this adds to the complexity of the electrical work and installation.

- Storage Solutions: Maximising space is often a priority. Built-in drawers, discreet cupboards, or hidden shelving seamlessly integrated under the staircase can be incredibly practical but require custom joinery.

- Custom Millwork/Joinery: Decorative newel posts, ornate carvings on stringers, or unique skirting designs add layers of sophistication and intricate detailing, demanding highly skilled craftsmanship.

- Soundproofing/Acoustic Design: In some cases, specific materials or construction methods might be employed to reduce sound travel, particularly in open-plan homes, adding another layer of cost.

- Automated Features: While less common, bespoke projects can incorporate automated elements for hidden doors, motorised storage, or advanced lighting controls, pushing the boundaries of custom design.

Each of these elements contributes to the unique, tailored nature of your bespoke staircase, making it perfectly suited to your lifestyle and home.

The human element: design, build, and installation

Behind every stunning bespoke staircase is a team of dedicated professionals whose expertise directly influences the new staircase cost. The human element—from initial design to final installation—is critical to achieving a flawless result.

Design & Engineering:

- The initial design process, including detailed 3D rendering, precise measurements, and complex structural calculations, is an integral part of the cost. More intricate and innovative designs naturally require more engineering hours and expertise.

- Architects and specialised designers are crucial in translating your vision into a practical and breathtaking reality, ensuring compliance and aesthetic excellence.

Manufacturing & Fabrication:

- Bespoke staircases often combine the best of both worlds: precision machine production for core components and exquisite hand-craftsmanship for intricate details and bespoke joinery.

- The level of precision required for complex joints, unique components, and perfect finishes demands highly skilled artisans, which is reflected in the labour cost.

Installation:

- The complexity of installation on-site is a significant factor. Difficult access, existing structural challenges, or multi-storey installations will increase the time and manpower required.

- Time required for installation: Longer, more intricate installations, especially for curved or floating designs, will incur higher labour costs.

Conclusion: investing in enduring quality and design

The cost of a new staircase – particularly a bespoke one – is a direct reflection of its unique design, the quality of chosen materials, any integrated features, and the unparalleled level of craftsmanship involved. It’s important to view this as more than just an expense; it’s a strategic investment in a durable, beautiful, and highly functional centrepiece that adds significant architectural value and personal enjoyment to your home for decades to come.

At Apex Staircases, we are committed to transforming your vision into an exceptional reality. We understand that how much a new staircase costs is a key question, and our goal is to provide transparency and value at every stage. We pride ourselves on creating bespoke staircases that are not only stunning but also perfectly engineered to meet your exact specifications and budget.

Ready to explore the possibilities for your home?

Contact Apex Staircases today for a personalised consultation and a detailed, transparent quote tailored to your specific vision and requirements. Let us help you craft the perfect staircase that elevates your home’s design and value.